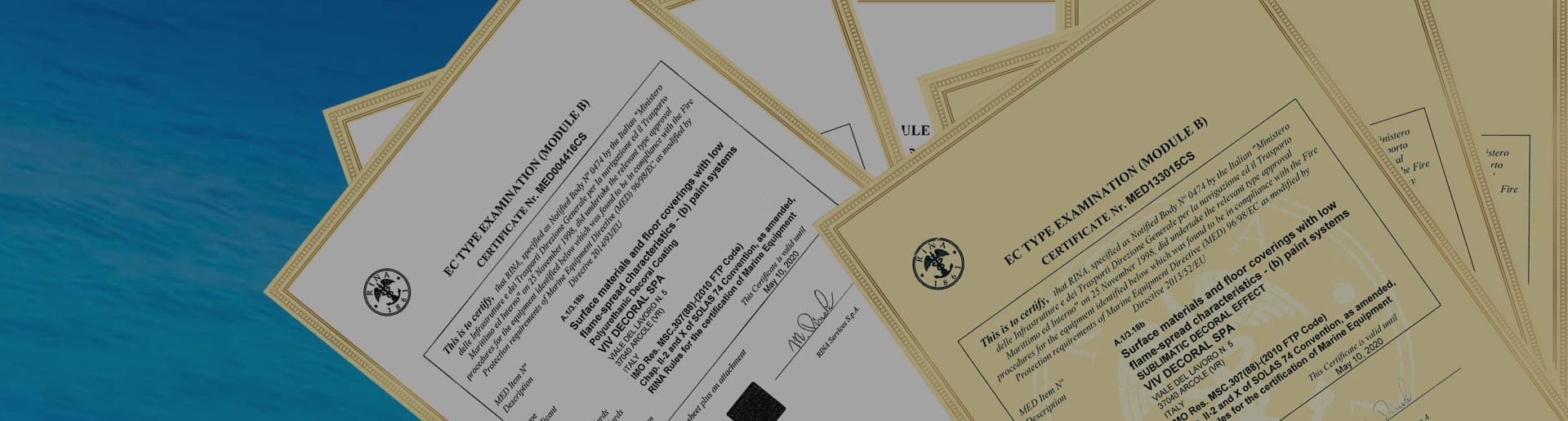

Viv Decoral® has a long experience in the shipbuilding sector, offering turnkey solutions for yacht and cruise interiors. We developed powder coatings and heat-transfer films with low-flame spread characteristics in compliance with MED (Marine Equipment Directive) requirements Module B as certified by RINA S.p.A.

POLYURETHANIC DECORAL COATING

Polyurethanic Decoral® Coating finish (RAL, NCS, Pantone, sample matching) is obtained through our powder coating process. The production cycle consists of applying special polyurethane powders (Decoral® System polyurethane powder coating) after having pretreated the surface.

Our powder coatings meet Qualicoat requirements (approvals P-0506, P-0617, P-0832 and P-0865).

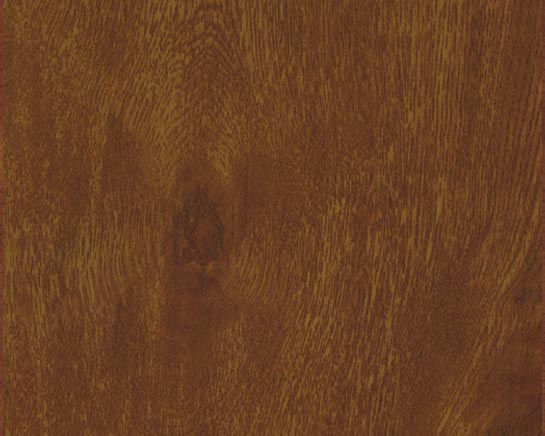

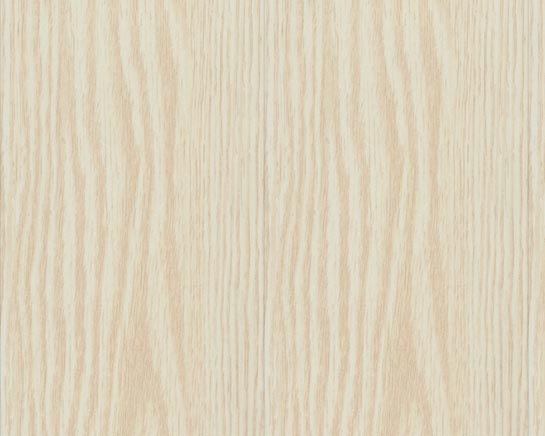

SUBLIMATIC DECORAL EFFECT

Sublimatic Decoral® Effect is obtained through the sublimation process, which includes the application of special polyurethane powders (Decoral® System polyurethane powder coating) and heat-transfer using sublimation films (Decoral® System heat transfer film). Such films faithfully reproduce real kinds of wood, showing flames, knots, light and dark areas.

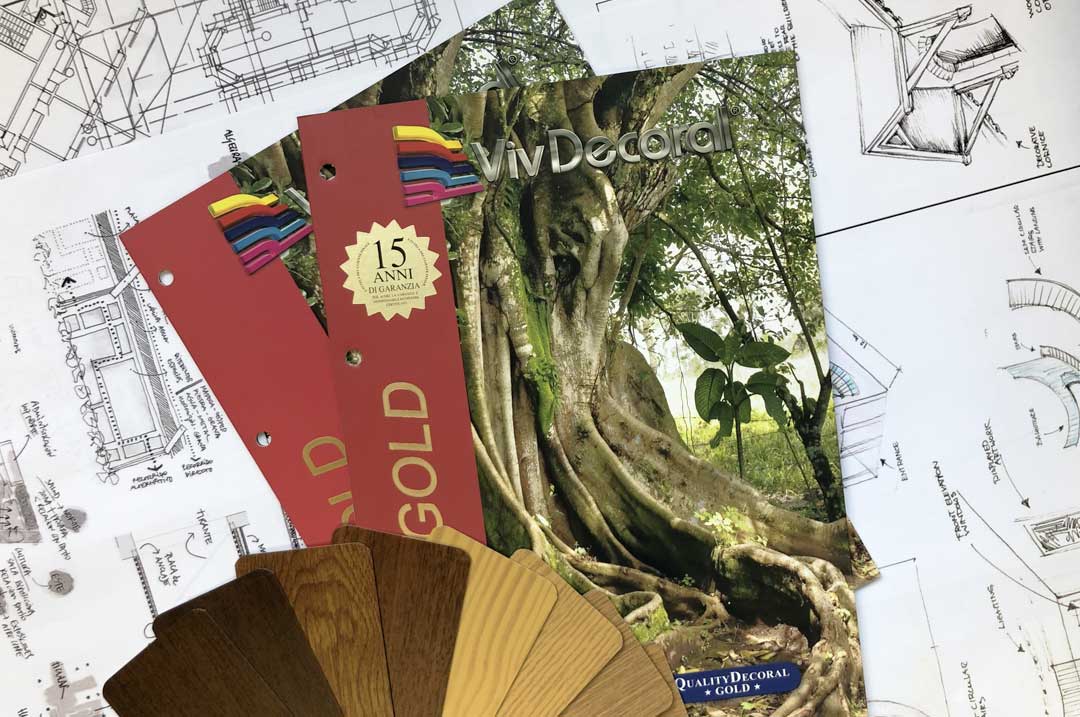

QUALITYDECORAL® GOLD & PLATINUM

Finishes that meet Qualideco Class 2 requirements

QualityDecoral® Gold is a self-certification for those finishes (specific combinations of Decoral® System super-durable powder coatings with hyper-durable heat-transfer films) that have a very high resistance to atmospheric agents, three times higher than standard finishes.

Such finishes consist of specific combinations that have successfully passed severe tests, i.e. 2500-hour accelerated weathering and 3-year natural exposure to Florida’s harsh climate.